Box Smarter with Right-Sized

Automated Packaging

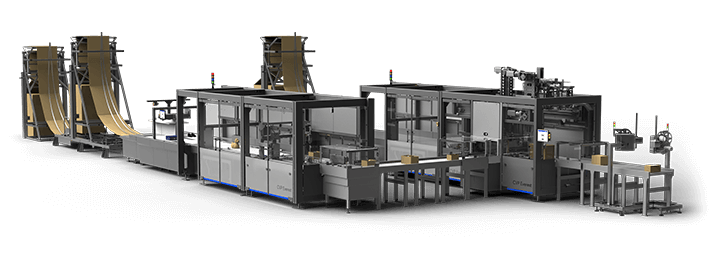

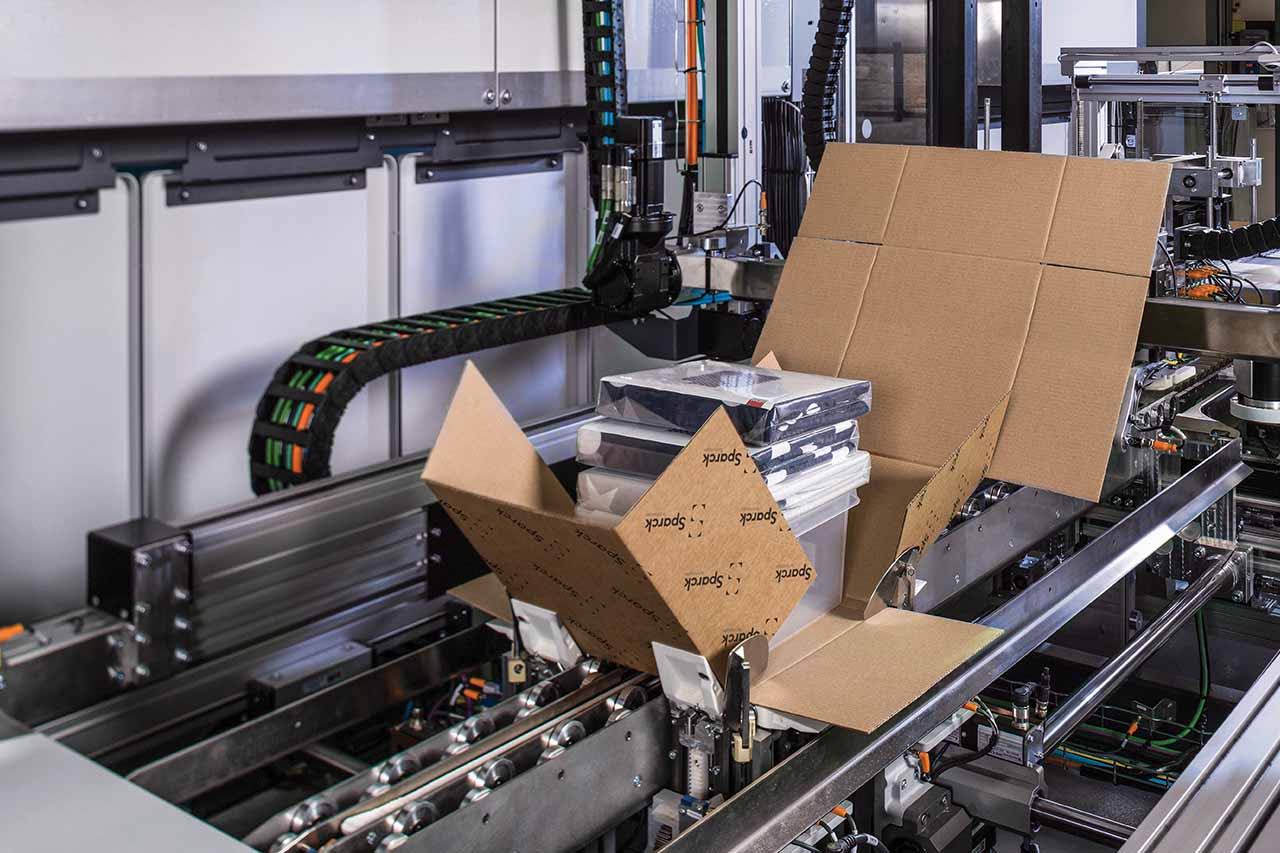

The CVP Automated Packaging Solutions are inline auto-packers. Made by Sparck Technologies (formerly Packaging by Quadient), this fit-to-size packaging technology will size, construct and label each custom order, creating the perfect package and eliminating the need for void fill materials. Automated packaging allows you to keep pace with the increasing numbers of online orders even during peak times. Companies worldwide benefit from a seamless packing process, saving labour costs while reducing box volume and corrugate consumption.

What Packaging Challenges Do You Want To Solve?

LABOR

Auto-boxing helps manage labor fluctuations while fulfilling orders in a timely, cost-effective manner and creating better warehouse efficiencies.

SHIPPING VOLUME

Why pay to ship air? Auto-boxing will reduce shipping volume and material usage due to an optimized sized box.

THROUGHPUT

Boost the speed of your parcel packaging process, up to 1000 boxes per hour, and get orders out the door quicker than ever.

RELIABILITY

Automated packaging ensures consistent throughput and a fit-to-size box is made everytime. Great control means more uptime and higher quality.

How Auto-Boxing Works?

Place order on induct station

Place order on induct station

Single- or multi- item orders can be processed by one operator for maximum packaging productivity.

Scanner captures 3D image

Scanner captures 3D image

Each unique order is scanned to determine the minimum box size required.

Scanner captures 3D image

Scanner captures 3D image

Each unique order is scanned to determine the minimum box size required.

Auto-boxing of order

Auto-boxing of order

Corrugate is custom cut to eliminate unnecessary volume and the need for void fill. Order is then auto-boxed in one seamless process, every three to seven seconds depending on the machine.

Box is sealed, weighed and labeled

Box is sealed, weighed and labeled

Every box is securely sealed, weighed on the in-line scale, and automatically receives a carrier-compliant shipping label.

Box is sealed, weighed and labeled

Box is sealed, weighed and labeled

Every box is securely sealed, weighed on the in-line scale, and automatically receives a carrier-compliant shipping label.

The Proven Performer.

Auto-boxing is all we do.

And we do it better than anyone.

Powered by

Sparck Technologies

Meet the mid-sized and enterprise-level companies who are benefiting from the efficiency and flexibility of our auto-boxing technologies.

More stories from our auto-boxing nation.

Powered by

Sparck Technologies

Meet the mid-sized and enterprise-level companies who are benefiting from the efficiency and flexibility of our auto-boxing technologies. More stories from our auto-boxing nation.

With this auto-boxing technology, we expect savings to be more than a half-million dollars in its full year of operation.

In partnership with Sparck , we are constantly reviewing the CVP Impack and its capabilities which has led to a great success. Sparck is always prepared to review and improve itself on the basis of someone else’s insights. That makes them very strong in my eyes.

In terms of shipping volumes, our calculations indicate that the two CVP Impack machines will offer a reduction of 92 truck loads a year, due to the space savings of fit-to-size packaging.

The uptime and performance is great, and the ROI has outperformed our projections. The CVP Impack has hit just about every metric we set for it.

Ready to be a fearless auto-boxer?

We’re here for you, and we are wearing our thinking caps.

Get in touch with our team to start the conversation.